What is an MRP? A Simple Solution for Manufacturers Facing Production Challenges

Running a manufacturing shop comes with its fair share of headaches. Whether you're struggling to keep up with customer demand, manage your inventory, or maintain a steady flow of production, these are signs that you might need a better system. Here are some common pain points manufacturers face:

Frequent Stockouts

Running out of critical materials can bring your production line to a standstill, delaying orders and hurting customer relationships.

Excess Inventory

To avoid stockouts, you might end up overstocking, which ties up your cash and space in materials you don't need immediately.

Unpredictable Production

Trying to plan production based on shifting demands without clear insights into material needs can lead to chaotic scheduling, downtime, and missed deadlines.

Waste of Resources

Guessing how much material to purchase often leads to waste, unnecessary costs, and inefficiencies that impact your bottom line.

Difficulty in Scaling

As your business grows, tracking materials and managing production by hand becomes unsustainable, leading to more errors and inefficiencies.

This is where an MRP system (Material Requirements Planning) steps in. An MRP system is designed to address these pain points by providing visibility into your production needs and helping you plan more effectively.

Why your business needs MRP

Avoid Stockouts and Overbuying

By predicting exactly how much material you’ll need based on your current and upcoming orders, you can ensure you have just the right amount of inventory, when you need it.

Improve Scheduling

MRP helps you generate production schedules that align with material availability, reducing downtime and making sure your orders are delivered on time.

Cut Costs

By minimizing excess inventory and waste, and improving the efficiency of your production, you’ll see a reduction in operational costs.

Prepare for Growth

As your business scales, the system scales with you, automating more processes and helping you manage larger volumes of work with less manual effort.

Try now the system and explore its possibilities.

Choose the apps you need and access a demo right now.

But What If MRP Isn't Enough?

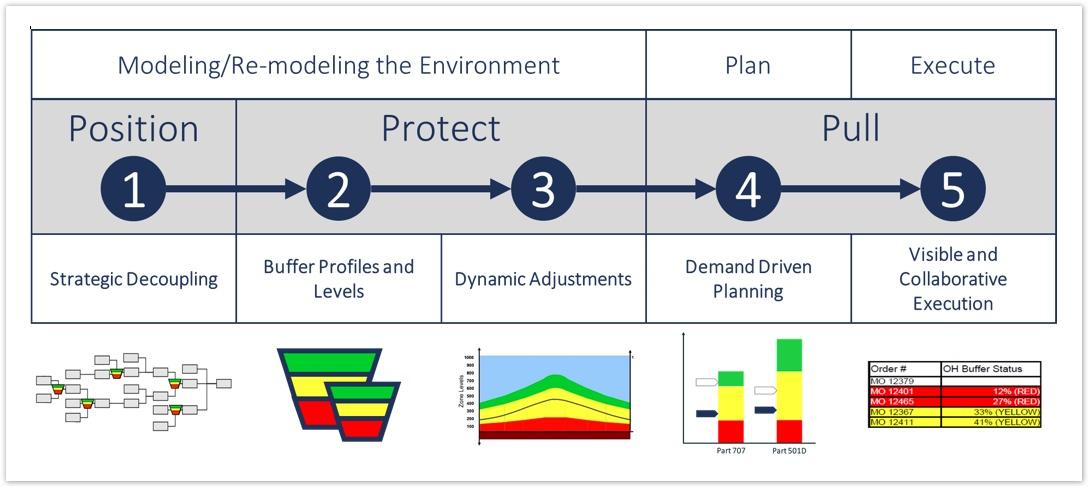

Demand Driven MRP helps you adapt to actual needs

Traditional MRP systems work well for manufacturers with predictable demand, but they can struggle when demand fluctuates or when customer orders become more unpredictable. This is where Demand Driven MRP (DDMRP) comes in.

DDMRP takes MRP a step further by responding dynamically to real-world demand. Instead of relying purely on forecasts, DDMRP ensures you only produce what is needed, when it's needed, by constantly adjusting for actual customer orders. This means less risk of overproduction or underproduction, and a more agile, responsive manufacturing process.

In short, whether you’re just starting out with MRP or looking for a more advanced, demand-driven solution, both systems can provide much-needed control over your production and inventory processes, allowing you to reduce waste, lower costs, and improve overall efficiency.

Try the system in a simulation environment.

Discover how our MRP can transform your business by improving planning, inventory, and resource control in our Business Games. Get access with just a few clicks.

Start now!

Trusted by