Unleash the full potential of your supply chain and

become Demand Driven.

Reduce your Inventory Levels

Typical DDMRP implementations result in 30-70% inventory reductions, even in environments of high variability and volatility. Because DDMRP self adjusts the inventory levels to what your customers need, with no excess or shortages, right sizing your inventory levels.

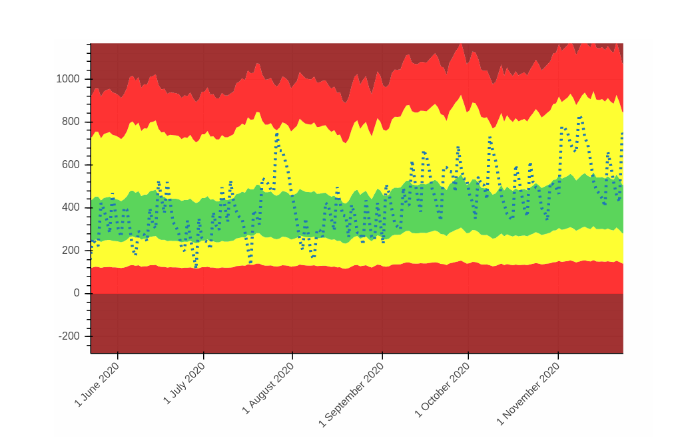

Variance Analysis, Projections

and Simulations

Variance analysis allows to you reflect on the past performance of the model in order to improve your processes.

Projections and Simulations allow you to project the Operating Model into the future, in different scenarios, allowing you to:

Provide forecast information to your suppliers

Identify future capacity problems

Identify future working capital requirements

Identify future working capital requirements

The Key Components of the Demand Driven Operating Model

The Demand Driven Operating model is a supply order generation, operational scheduling, and execution model utilizing actual demand and strategic decoupling points to create a system that promotes and protects the flow of relevant information and materials. By properly configuring Demand Driven MRP parameters with the Demand Driven Sales and Operations Planning process, the system will combine inventory records and actual demand to generate supply orders.

In the following articles we explore different parts of this complete system and present more information and tools included in ForgeFlow Demand Driven.

Try now the system and explore its possibilities.

Choose the apps you need and access a demo right now.

This simulation of your business allows you to discover,

using our Demand Driven, how all your needs are covered.

Education enables change in your organization

As Demand Driven Planner Instructors and Odoo partners we offer high quality training programs to enable a successful digital transformation in your organization.

Scale smarter, grow faster.

ForgeFlow Cloud has you covered.

No credit card required. Access in minutes.