Assess inventory levels with the On-hand Distribution Report

Having excess inventory is harmful to a company because it ties up valuable financial resources that could be better utilized elsewhere. This idle stock becomes a liability, as it not only requires storage space but also incurs additional costs such as insurance, security, and maintenance. Moreover, excess inventory increases the risk of obsolescence, where products may become outdated or spoiled, leading to further financial losses. For this reason, it is fundamental to monitor stock levels and ensure they are appropriately dimensioned for actual demand.

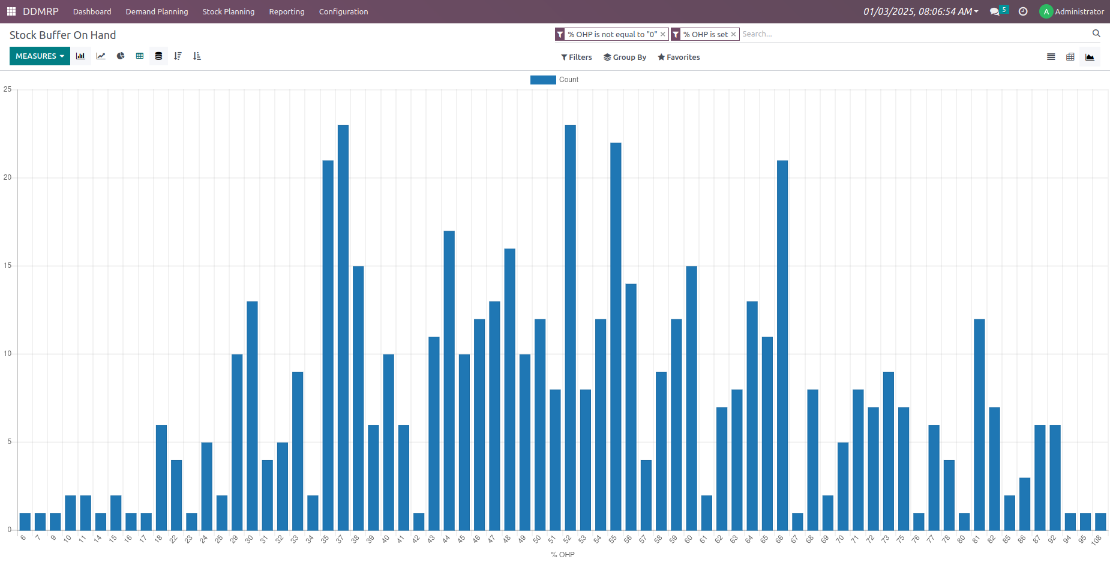

On-Hand Distribution Report

This report is a valuable tool to assess how well stock levels are maintained, and whether the on-hand inventory stays within the target range. It monitors the on-hand quantity of each item on a daily basis by comparing it to the optimal inventory levels. The report presents this data as a percentage of the ideal inventory threshold, providing a comprehensive overview of stock amounts across all items and historical dates.

In the image below you can see the report results for a company. Along the horizontal axis, each point represents a specific percentage of the optimal inventory threshold. Meanwhile, the vertical axis indicates the cumulative number of past dates where the inventory level was in that position, aggregated across all stocked components.

Watch the report in action

Explore our related articles

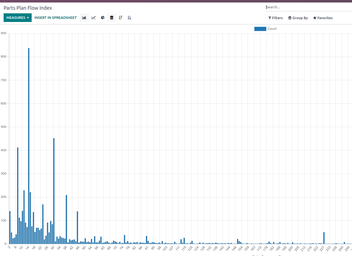

Optimize system velocity using the Flow Index Report

This report analyzes order frequency and inventory buffers to measure product movement speed. Discover how to manage excess inventory, balance costs, and improve system velocity.

Discover

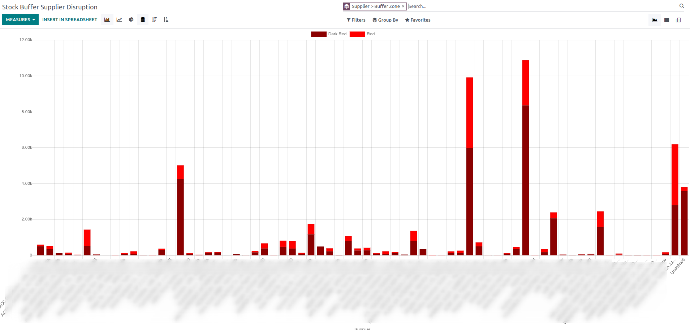

Improve supply reliability with the Supplier Disruption Report

This report evaluates supplier reliability by analyzing the time stock levels spend in critical buffer zones. Learn to identify unreliable suppliers and take corrective actions to maintain a steady flow of materials.

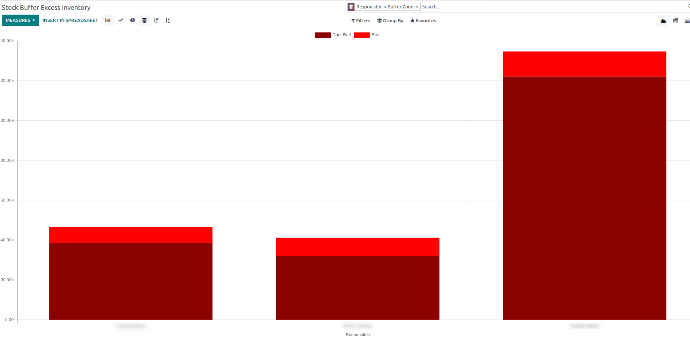

Evaluate stock managers reliability with the Excess Inventory Report

Use this report to evaluate the effectiveness in stock excess control. It analyzes the cost of excess inventory held, enabling comparisons with past periods to understand the evolution of the performance. This allows for a comprehensive understanding of inventory management efficiency.